ENERGY OPTIMISATION IN EDIBLE OIL REFINING WITH ABSORPTION CHILLERS

- coolingcommunicati

- Jun 26, 2020

- 2 min read

Population growth and changing diet trends place increasing demand on the edible oil industry. Aiming to meet the demands at optimal cost, the industry leaders are increasingly looking for sustainable technologies so that the processing cost and energy consumption is kept low, aligning with the environmental emission norms.

Vapour absorption technology serves as the right option for processing utilities in oil refining units.The absorption machines find potential applications across the refinery line in processes like solvent extraction and post-refining cooling. Since run on heat from steam, hot water, or exhaust, absorption chillers leave the least possible carbon footprint. Hence, they are also the environmentally viable solutions for cooling in the oil refinery units.

Cooling Requirements in Oil Refining

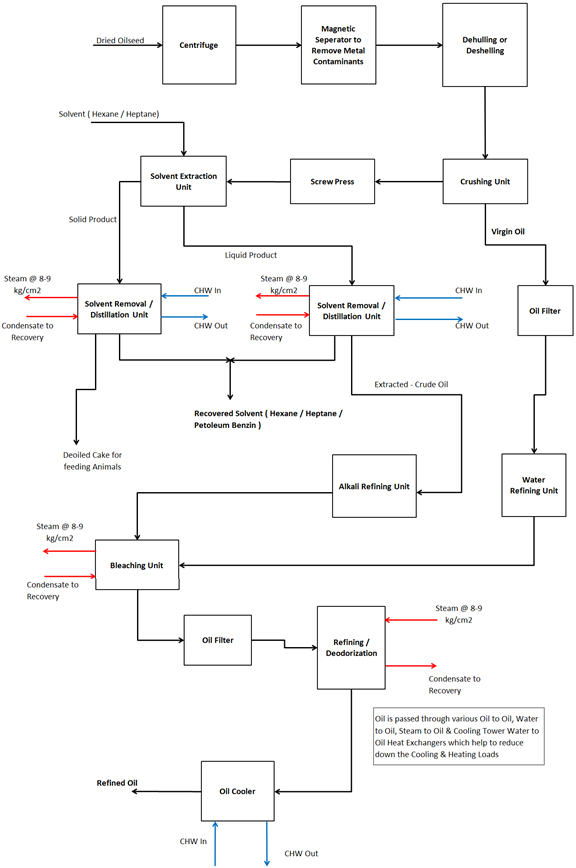

Edible oil undergoes intensive refining phases before the final product is synthesized. The line includes cleaning of the seeds, preheating, flaking, conditioning, pre-pressing, solvent extraction, and storage. Modern extraction utilities yield 95% of oil with majority of the solvent recovered as well.

Solvent extraction is the process of separating the residual oil from oil seeds. The process begins with grinding the seed, followed by purging the seed cake with hexane. The process results in releasing the oil in the seed. The solvent is then “flashed off” by heating the oil in a sealed chamber. The oil/solvent blend is next heated to 100º C, the vapour of which is passed through a condenser. The condenser in the solvent removal unit requires chilled water at a temperature lesser than the cooling water from the cooling tower.

Absorption chillers utilise steam from one of the plant’s utilities and offer chilled water at the desired temperature for the condensers. The condensate (water) from the chiller is used to cool the oil cakes, which serves as animal food.

Benefits of absorption chillers in refining industry

Uses low-grade heat from the plant saving significant operational costs.

Can be operated at designed COP

Low payback period

Low maintenance cost

No emissions of ozone-depleting CFS

Edible oil refineries host a range of potential opportunities for efficiency enhancement and emission reductions. Replacing the energy-hogging conventional utilities with absorption chillers in refineries can improve operational efficiency and meet sustainability standards alike.

Comments